A Practical Approach to Exterior Insulation

Discover a cost-effective system for applying continuous insulation that can help you achieve targeted R-values.

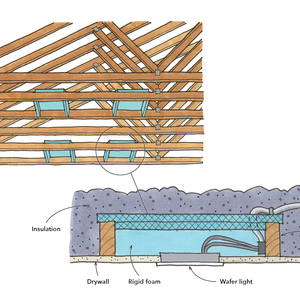

Applying continuous insulation, such as rigid foam, along the exterior of a building can prevent thermal bridging and improve energy efficiency. However, running rigid foam in an unbroken fashion can be challenging across transitions, such as foundation to walls and walls to roof.

Several methods exist to address these challenges, but a recent innovation stands out for its relatively low cost and overall practicality. The InSoFast X-Bracket System is comprised of composite plastic brackets designed to secure furring strips and siding in place while creating a void to fill with insulation.

The system can achieve targeted R-values by supporting insulation depths from 21/2 in. to 41/4 in. without the need for labor- and material-intensive methods like Larsen trusses or double-wall construction. The X-Bracket System also excels in retrofit applications, allowing for the installation of continuous insulation over existing siding.

Proper Installation

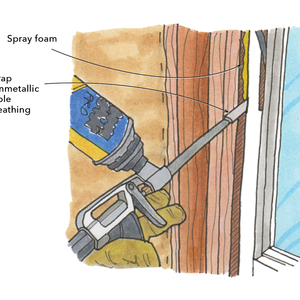

The success of the insulation install depends on proper setup of the X-Brackets. For spray-foam installations, the process begins with attaching the brackets to the sheathing with screws, nails, or adhesive, and then attaching furring strips to the brackets to secure the siding or roof sheathing.

The foam insulation (open or closed) is applied with a 1/4-in. setback from the furring strips to allow cross-ventilation, while 3/4-in. furring creates a vertical gutter for drainage and drying. For dense-pack insulation, a water-resistive barrier, such as housewrap, is stretched over the brackets to form a cavity for the insulation.

Furring strips support the housewrap, holding it in place as the insulation is pumped in. Dense-packing often requires specialized installation techniques and reinforced barriers to ensure long-term performance, so coordinating with your insulation contractor is key.

Tried and True

The X-Bracket System has demonstrated impressive performance in testing, withstanding wind speeds of over 200 mph and lateral loads of over 300 psf under specific fastening configurations. Right now, installations are primarily focused on simple structures; upcoming projects will test the system’s adaptability to more complex designs.

The brackets, priced at approximately $1.50 each, contribute to an assembly cost of $5 to $8 per sq. ft. While the X-Bracket may not become a mainstream solution—particularly when a simple layer of rigid foam can achieve code compliance, and many of the same benefits—its ability to simplify high-performance retrofits and reduce costs could make it a valuable tool for specific applications.

— Fernando Pagés Ruiz; builder and ICC-certified residential building inspector.

RELATED STORIES

- The Case for Continuous Insulation

- Is Adding Exterior Insulation When Re-siding Your Home Worth the Cost?

- A Deep Dive Into Continuous Exterior Insulation

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Caulking Gun

Utility Knife

Insulation Knife