Big Doors Have Big Challenges

Engineered materials and vacuum-press laminations prevent warping and keep a tall, flush-panel door from being excessively heavy.

This article details the process of building oversized flush-panel doors, addressing common challenges like warping and weight. The doors are constructed with lightweight engineered materials to ensure stability while remaining manageable during installation.

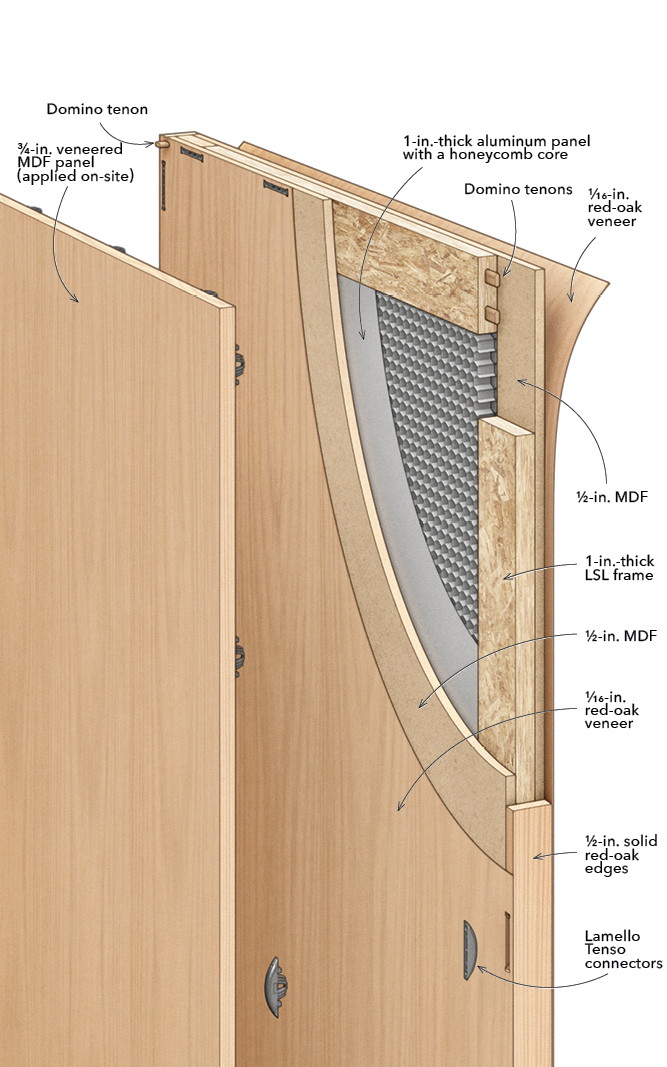

The frame is assembled with precise joinery and the core is laminated using a vacuum press for even pressure. After adding solid red-oak edgebanding and veneering both sides, the author installs the doors on-site, where he adds pivot-door hardware and a finished veneered panel to complete the modern look.

Disappearing Doors

Hidden doors can’t just be hidden the day you install them—they need to stay hidden. When I thought about buying the doors for this project, and the fact that most manufacturers don’t warranty doors of this size, it was clear that I had to build them. Meant to disappear into a paneled wall, these doors needed to start and stay flat.

Another concern was weight. Using high-quality pivot-door hardware would help manage the weight once the doors were installed, but I needed to be able to install and adjust them. Some of the construction details helped with both stability and keeping the doors from getting too heavy. I got the idea for the aluminum honeycomb core that I ordered from Flatiron Panel Products from Ken DeCost of NS Builders, who took a similar approach to some closet doors.

I’ve built many doors, but this project definitely required research and some novel approaches to ensure a true fit and a long-lasting door. These doors were built for a unique project and were given an applied veneered-MDF panel during installation. The assembly, however, could be modified for a number of different door styles. If stability and weight are concerns in your door project, consider adapting the materials and techniques I’m sharing here.

That Modern Look: While this door construction would work for a number of door styles and in many situations, these were designed to disappear into a modern veneered wall paneling, which Casey shared in “That Modern Look” from FHB #329.

Layered Assembly With a Lightweight CoreThese doors are over 8 ft. tall and nearly 3 ft. wide. A solid wood door would have been prohibitively heavy. I chose engineered materials and a layered assembly that starts with an LSL frame and a lightweight aluminum panel. The first glue-up was to apply an MDF panel to each side of the frame. I added solid red oak all around the edges of the door before the second glue-up, which was to add red-oak veneer to both sides of the door. One side will have a red-oak-veneered panel applied when the doors are installed, but when building laminated doors like this, the layers need to be the same on both sides of the door. Equalizing the stresses on both sides makes the door more stable.

|

Prepare the CoreAt the center of the doors is the LSL frame and the aluminum panel. I assembled the frame with loose tenons for alignment using the Festool Domino and then glued up the rails and stiles with yellow glue. It was important to start with a square frame, which I double-checked before clamping. The doors would be cut to finished width in the shop, and the top squared, but I left the bottom long to be trimmed on-site. I put an aluminum-cutting blade in my track saw to cut the panel, tested the fit, and thoroughly vacuumed up the aluminum shavings before preparing to laminate the core with an MDF face on each side.

|

Prepare the PressI don’t use my vacuum press that often, and even if I did, I wouldn’t want to risk a glue up by not checking that it is working properly first. Before starting this glue up, I was careful to make sure all surfaces were very clean, including the bag, and I mostly used an air hose to do this. Not only does air need a path to evacuate the bag, but the glue up needs to be set on a flat surface. A sheet of melamine with a grid of grooves serves both purposes. It’s called a platen, and it includes a port that I connect to the vacuum pump’s hose. (There’s also a hole in my table to connect the hose to the bag.) I slipped a dry-fit of the door assembly into the bag to test the pump and the seal before any glue was applied.

|

Glue It UpI used two-part West System epoxy for the first glue-up, which included skinning the LSL frame and aluminum panel with ½-in. MDF on each side. I sanded only the MDF to give it a bit of tooth for the epoxy to grab. The LSL material has plenty of texture, and the aluminum panel comes ready for epoxy. I just had to remove the protective plastic and give it a quick cleaning. I applied epoxy to every surface using a paint roller and a special ¼-in. “adhesive and epoxy” nap. Once I had all the glue applied and all the layers stacked, I shot a few pin nails to keep everything aligned as I got it into the vacuum press. For even pressure, I put a melamine caul on top of the assembly. The caul also has rounded edges to protect the bag from puncture. I left the door in the vacuum press for 24 hours.

3.) Glue all surfaces.

|

Veneer Both SidesWhen the first glue up was ready to come out of the vacuum press, I added solid red oak to the long edges of the door. Using solid material instead of veneer allowed me to trim the width of the door later and to add the hinge-side roundover needed for one of the doors to work with the pivot-door hardware. After that, I flushed up the edging with a router. To glue up the veneer for the door, I matched the grain and trimmed and cut a straight edge on each piece. Even though one side of the door will be covered by a plywood panel that matches the wall paneling where these doors will be installed, it’s important to veneer both sides of the door. Even layers help keep the door from warping. When the veneer was ready, the door went back in the vacuum bag for another 24 hours.

|

Wrap It Up On-SiteI built these doors a bit taller than needed because they were to be installed in a house that was still under construction, and I was not able to verify the height of the finished flooring before I started. Not only did I trim the doors to final height on-site, but I also installed the Rixon pivot-door hardware on-site, as well as the finished veneered panel on one side of the door, which I fastened with a combination of Domino tenons for alignment and Lamello Tenso connectors for a sturdy hold.

|

— Casey Knips; owner and operator of True Fit Carpentry, a custom trim and cabinetry company in the Twin Cities. Photos by Brian Pontolilo, except where noted.

RELATED STORIES