Drywall Taping Tools

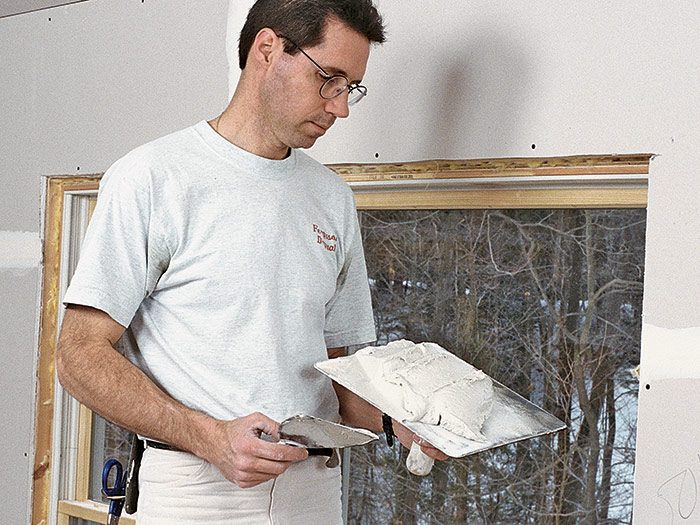

Taping knives and trowels are the tools of choice for taping by hand, but mechanical taping tools are also making inroads.

It used to be that a trowel, a couple of taping knives, a roll of paper tape, and a pail of joint compound were all that you needed to do a typical taping job. Nowadays, there are many types and sizes of trowels, various options for reinforcing seams, and so many different kinds of joint compounds that you may not know where to begin when deciding which one to use.

Hand taping tools

There are a variety of trowels and taping knives that I use for taping, all of which are available in different sizes for different applications. As I discuss each tool, I’ll mention the size that I use most often and, where appropriate, explain what features to look for when purchasing a trowel.

Taping knives, which are available in widths from 1 in. to 6 in. (in 1-in. increments), are used for taping seams and corners and covering fasteners. The wider widths often have a metal end on the handle for resetting nail heads. Narrower widths come in handy for taping tight areas (for example, the often-narrow space between a doorframe and a corner). I use a 6-in. knife more than any other size. Whatever the width of the knife, it should be fairly stiff (not too flexible).

| WORK SMART: Cheaper, flimsier knives are harder to work with and tend to leave too much joint compound on the surface. Stiffer knives give you more control over the amount of compound left on the surface. |

When buying a taping knife, look for one that has a little curve in the blade when viewed from head on. If you can’t find one, you can put a slight curve in the blade by bending it over a rounded surface, such as a pipe. I use the convex side of the blade when taping. Because the curve helps keep the corners of the blade slightly away from the taping surface, the result is a smooth surface without the tool marks created by a flat knife blade. The knife blades are available in blue steel or stainless steel. It’s a matter of personal preference, but I have used both and, if anything, I prefer the stainless steel because they seem to last longer.

| WORK SMART: I choose a taping knife or bend one so that it has a crowned or convex side. This is the side I work with. The edges of the knife are lifted slightly off the compound surface, which reduces tool marks. |

A square-cornered taping knife cannot reach into a corner very well if the corner is less than 90 degrees (for example, at the intersection of a sloped ceiling and a wall or at the top of a cellar stairway). In these areas, I use a pointed trowel, which can easily be made by cutting off the sides of an old 6-in. taping knife. A small pointed mason’s trowel also works well for this purpose.

Hawks are used to hold large quantities of joint compound when working with a taping knife. These tools have a square aluminum top with circular grooves to help prevent the joint compound from sliding off, and a short, straight handle centered on the underside. Hawks are available in sizes from 8 in. to 14 in. square. I prefer to work with the largest size only because it saves a few trips back to the compound bucket. A pan is commonly used instead of a hawk—especially when compound of a thin consistency is used. A pan also comes in handy as a mixing container.

Curved or beveled trowels have a slight curve in the blade that is about 5/32 in. deep. They are available in lengths from 10 in. to 14 in. and in widths of 4 in. and 41/2 in. I prefer to use a curved trowel rather than a flat trowel because the curve allows more control of the amount of compound I want to leave or remove. I usually like to leave a very slight crown in the compound, which will disappear when the compound shrinks a little and is finish sanded.

I use the 4-1/2-in. by 14-in. curved trowel for feathering and finishing most seams, as well as for holding joint compound while applying it with a taping knife. It has many uses, and I always seem to have a curved trowel and a 6-in. taping knife in my hand while taping.

| WORK SMART: Use adjustable-angle knives to finish inside corners that are not 90 degrees. They work well for embedding the tape and feathering the joint compound. |

Wide straight-handled taping knives are much the same as narrow taping knives, except they have a metal reinforcing strip at the back of the blade. I like to use this style knife that is 8 in. wide to embed the tape on seams when I am using automatic taping tools. I use a wider 10-in. or 12-in. version when applying and smoothing out the final coats of joint compound on seams and outside corners, as well as for smoothing out large areas and seam intersections. Straight-handled taping knives are available in widths from 10 in. to 24 in. As with regular taping knives, they should have a slight curve in the blade and the corners should be rounded with a file. I use a 12-in. knife for most applications.

TROWEL CARE

|

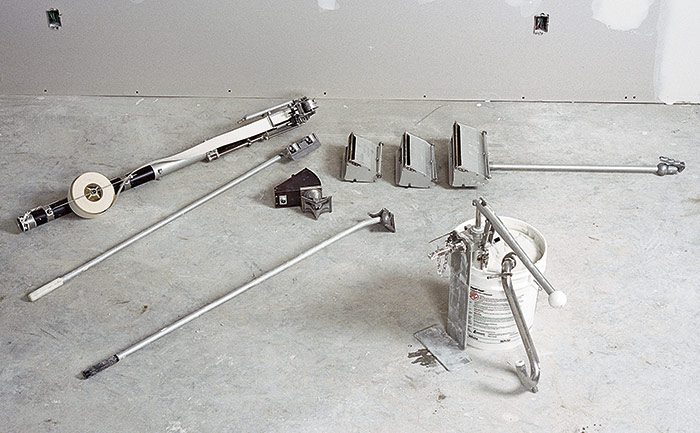

Automatic taping tools

Automatic tools are quite popular today because they cut down on labor, and there are mechanical tools available for each step in the taping process. Mechanical taping tools are expensive, but the cost of the tools is soon recouped because of the increased productivity and quite often increased quality of work. You can also rent these tools. I use them mostly when I’m taping larger jobs, but they also come in handy when I’m working on two or three smaller jobs at once.