Restore a Wood Window Sash

When repairs are in order, a steam box, an easel, and two-part epoxy are your best friends.

There’s a debate among preservationists and energy nerds, traditionalist and modernist, about what to do with old single-pane, divided-lite, weighted window sashes. They have lots of character and history, but also a big energy penalty compared to replacement options.

I won’t try to convince you to restore your old windows. But if you do need to repair a window sash, or a whole house worth of window sashes, I can help you get it done right and with as little frustration as possible. I learned a lot of lessons while tackling the restoration of a historic municipal building that is to become a museum for the city of Yankton, S.D., my hometown—a project for which I repaired, reglazed, and restored hundreds of wood sashes and their window frames. The work prepared me well for the job you see here, which was restoring the windows in my own 1920s bungalow.

Repairs take time

Restoring a 100-year-old window sash so it will last another 100 years means removing the old glazing putty and glass, stripping the frame back to bare wood to make any necessary repairs, priming, reinstalling the glass and glazing, and finally, applying a couple coats of paint. Though no one part of this process takes too long, there is a lot of downtime.

For example, I use a steam box to soften the glazing putty, which allows me to easily remove the glass without breaking it (though I’ve learned to expect to break about 20% of the glass on a bigger job). The steam will also soften the paint, but don’t be tempted to try to scrape it off along with the glazing. The steam will not only soften the glazing and paint, but the wood itself, making it more susceptible to damage from the scraping tools.

Even if I can manage to remove the softened paint without damaging the wood, the tools will leave the surface fuzzy and in need of a lot of sanding. Too much sanding changes the dimensions of the sash, which can result in a sloppy fit when it’s reinstalled in the frame. Rather than risk damaging the wood frame or the window not working right, I wait 24 hours for the wood to dry before scraping.

The steam box isn’t the only tool that makes this tedious job much more tolerable. I also use a shopmade easel to hold the sash upright while I scrape paint and apply glazing putty. One clamp holds the sash in any number of helpful orientations and the easel’s shelf and hook offer a handy home for putty, chalk, scrapers, sanders, and any other tools and materials that I want to have nearby.

It takes about 24 hours for any epoxy repairs to be ready for sanding and two weeks for the glazing putty to cure enough to be painted. This means that I’ve had to find a way to close up the window openings for a considerable length of time. I found a pretty slick and secure method that uses a couple strips of 7/16-in. OSB fit into the parting-bead groove and a larger piece to fill the opening. A few drywall screws lock everything into place. The beauty of this method is that no screws are driven into the window frame.

Lead is likely

If you are working on a house like mine, with single-pane wood windows—or, according to the Environmental Protection Agency (EPA), any house built before 1978—there’s a good chance that the window sashes will have been finished with lead paint at some point. Following the EPAs Renovation, Repair, and Painting program (RRP) to the letter is quite involved and also necessary if you are working on a client’s home. But you don’t have to assume that there is lead paint present. You can test the windows, as I did.

I found that my window sashes were finished with lead paint outside, but not inside. Because I am doing the work for myself, I was not required to follow the RRP rules. Since I am tackling a few sashes at a time and can work slowly and methodically, I took some precautions, but not enough to satisfy the EPA. For example, I did not set up a perimeter around the area when I was removing the window sashes. I did close off the door to the room and took care to vacuum with a shop-vac fitted with a HEPA filter as soon as the sashes were out. And I set up a wide perimeter of plastic sheeting under my easel while scraping. I wore a Tyvek suit, which never left the work area, as well as gloves and a respirator, and I used a spray bottle to mist the sashes as I scraped. I’m not suggesting that this is best practice. It was an amount of protection that I felt comfortable with at my own home. If I had been working at a client’s house, I would have followed the RRP rules.

While most of the products that I use to do this work are not harmful, I do recommend painting the sashes with an oil-based primer before glazing. This step should be done safely—either outside or in an area with excellent ventilation, while wearing proper respirator.

Not all old wood windows are in good enough shape to be restored. Sometimes replacement is the best option. But, if you decide yours are worth saving, it’s a job you should only do if you’re going to do it right.

Take Care When Removing The Sash

Old weighted-sash wood windows were built to be easily disassembled and repaired. Knowing how these windows were built before you start is helpful, but don’t assume parts are universal or even interchangeable from one window to the next. Label all the parts so you know where they go to make it easier to reinstall the sash later.

Steam The Sash To Remove The Glass

Use a steam box to soften the old glazing putty. To avoid thermal shock, which can break the glass, either put the sash in the steam box before firing it up, or leave the door open for a few minutes before inserting the sash. Put the sash in with the outside of the window facing up so the glass doesn’t fall out and break when the glazing putty softens usually in about 45 minutes to an hour.

Scrape It Bare, Then Repair

Let the sash dry for about 24 hours after steaming. Then scrape it down to bare wood to get it ready for repairs. In this case, the only issue was minor checking in the wood along the meeting rails. To contain paint chips and dust, set up plastic sheeting on the ground and mist the sash with water to keep dust down while scraping.

One Easel, Four Scrapers, And Two Epoxies

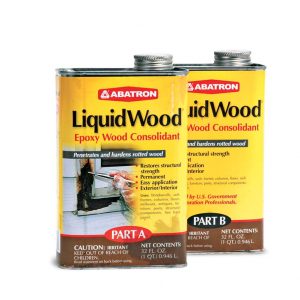

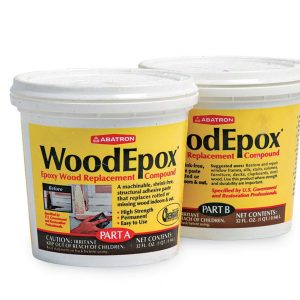

The right tools help you do the job quickly and well, and the right materials make the repairs durable. Take an hour to make an easel from framing lumber and not only will you be able to work standing comfortably upright, but you’ll be able to position the sash in all different ways to get the best angles for scraping (and later for glazing). Bahco makes excellent scrapers. They’re comfortable to use and the replaceable carbide blades come in many different profiles, allowing you to scrape paint from a sash’s numerous shapes and profiles without damaging the wood. Finally, two epoxy products from Abatron make long-lasting repairs: LiquidWood, which is applied first and penetrates the area in need of repair, and WoodEpox, which adheres to the LiquidWood and fills the damaged areas. Both are two-part epoxies mixed in a 1:1 ratio.

The right tools help you do the job quickly and well, and the right materials make the repairs durable. Take an hour to make an easel from framing lumber and not only will you be able to work standing comfortably upright, but you’ll be able to position the sash in all different ways to get the best angles for scraping (and later for glazing). Bahco makes excellent scrapers. They’re comfortable to use and the replaceable carbide blades come in many different profiles, allowing you to scrape paint from a sash’s numerous shapes and profiles without damaging the wood. Finally, two epoxy products from Abatron make long-lasting repairs: LiquidWood, which is applied first and penetrates the area in need of repair, and WoodEpox, which adheres to the LiquidWood and fills the damaged areas. Both are two-part epoxies mixed in a 1:1 ratio.

Reinstall The Glass

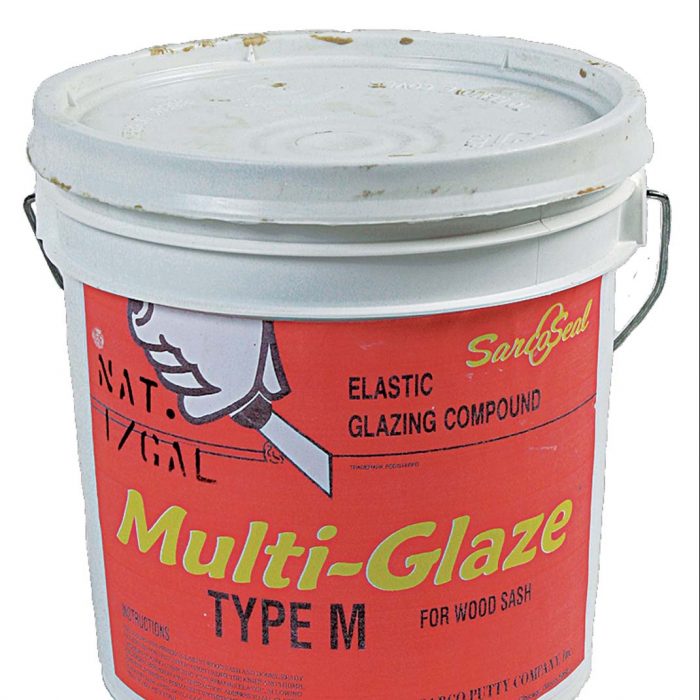

After coating the sash with oil-based primer, it’s time to reinstall the glass, bedding it in glazing putty. Glazing putty is linseed oil and chalk, so it’s helpful to have some extra chalk on hand to help make the putty workable and for cleanup. Any calcium-carbonate chalk, such as that used for lines on athletic fields, will work. You can find it at most hardware stores.

After coating the sash with oil-based primer, it’s time to reinstall the glass, bedding it in glazing putty. Glazing putty is linseed oil and chalk, so it’s helpful to have some extra chalk on hand to help make the putty workable and for cleanup. Any calcium-carbonate chalk, such as that used for lines on athletic fields, will work. You can find it at most hardware stores.

Glaze It, Then Leave It Alone

It’s important to tool the glazing so that it pitches away from the glass, but the amount and angle of the glazing will be determined by the size of the rabbet the glass fits into. If you go higher than the top of the rabbet, the glazing will be visible from inside the house. If you are too far below the top of the rabbet, there won’t be adequate pitch.

Work in the order shown here and when finished, keep the sash in its upright position until it is reinstalled. This will keep the glass from shifting and the most important glazing—at the bottom of the window—from being disturbed. Allow the glazing to set for about two weeks before painting, and wax the sides of the sash before reinstalling.

| 1.Upside Down

First, glaze the top of each pane. |

2.Sideways Next, glaze both sides of each pane. |

|

|

|

3.Right-Side Up Finally, glaze the bottom of each pane. |

4.Clean The Glass Again Brush the glass with chalk to remove any oil residue from the glazing putty. |

|

|

To see the process in action, check out these three related videos:

- How to Protect a Window Opening During Sash Restoration

- Use a Steam Box for Window Restoration

- How to Glaze a Wood Window

For more detail, including step-by-step photos on removing, steaming, scraping, repairing, reinstalling, and glazing a historic sash, click the View PDF button below.

View Comments

Some readers may not want to build a steam box. Plus, Steamboxing, drying, and sanding take lots of time, risks damaging the old wood, and don't work on interior trim. A low heat and handheld Speedheater™ can handle softening glazing and stripping paint with low infrared heat. No damaging the wood, releasing lead fumes, and applying it only once for glazing and once for paint stripping. Immediate removal of paint and glazing and ready for repainting and reglazing. 22 oz model or 4.4 lb model.

I'm planning to restore more than a dozen double hung sash windows in our 100-year-old stucco bungalow. They all are single-light, which is an opportunity to swap in dual pane glass, with commensurate increase in the counterweights. I realize I'll need to route the sashes to fit the thicker glass structures, but I've seen several YouTube vids doing just this. Any reason you opted not to try this? Did you attempt this with any of the hundreds of sash windows you've renovated? Any words to the wise? I much appreciate your easel idea! I'll likely build one that holds three sashes! Great article!