Templating Techniques for Countertops and Floating Shelves

Fit finished parts into tricky spaces, with no gaps and no risk.

Synopsis: Finish carpenter Stefan Straka shows how to build a template with one piece or with strips to suit different situations. In this article, he goes through three projects and the templating techniques used in each situation: a countertop with overhangs and a sink cutout, floating shelves that fit between three edges, and shelves that meet two edges.

When a finished part needs to be fit to a single surface—be it a crooked wall or a bumpy fireplace—a carpenter or cabinetmaker will “scribe” the part, transferring the contours of the adjoining surface directly onto the part before removing the waste for a gap-free junction. I covered this topic in a recent article, Perfect Scribing for 5 Types of Tasks, in FHB #310.

But when that part bumps up against two or more surfaces at once, it’s risky to transfer their shapes directly to the workpiece and start removing waste from that valuable material, hoping all of the edges end up perfect at once and that the part lands where you want it to. The classic example is a countertop being fit into an enclosed three-sided space.

In these cases, finish carpenters make a template—using cheap, thin materials—and first fit the template into the space before transferring its shape to the part being installed. This usually incorporates scribing as well, which is why I covered that topic first. Getting all of the fitting done on the template before committing to your finished material removes most of the risk. Once the template fits perfectly, you can transfer its shape to the workpiece and cut away the waste with confidence, knowing you’ll get a seamless fit. In many cases, the templating process also helps me identify problem areas I might have otherwise missed.

Strip templates for countertop overhangs and cutouts

Even with seemingly straightforward finishes like island countertops, a template can help dial in overhangs and offsets while accurately positioning cutouts—for a sink, rangetop, or other penetrations. Here, I used a strip template to lay out the sink opening and lock in the overhangs on a white-oak countertop, which I then cut and finished in the shop.

I start by measuring and cutting template strips to length. I chop the ends of the strips at a slight angle so they meet at a point to create sharp inside and outside corners. It’s important to exercise care when gluing the strips together, as the shape you create is the one you will be cutting out on your finished parts. Hot-melt glue cools to a semirigid state in just a few seconds, and any tension or movement after the glue goes on can weaken the joints, rack the template, or pull the strips away from their mating surfaces. On the most important intersections, I hold the strips in place a bit longer after gluing to ensure they don’t shift.

Working on top of the cabinets, I templated the perimeter of the countertop and then added more strips to stiffen the assembly and mark the sink cutout. I included location marks for aligning the finished countertop, and I marked the corner-radius dimensions on the template. After a once-over to confirm that the template was accurate, I transferred the outline to the countertop; cut it, routed it, and sanded it to size; and applied a finish before bringing it to the site for installation.

Two ways to build a template

When the finished part needs to fit against more than two surfaces or overhang an object perfectly, or if it includes multiple cutouts, I form a template from strips, pressing them against the outside of the space and hot-gluing them together at the corners. If the surfaces are curved or otherwise irregular, you can scribe and fit the strips independently before gluing them together. With just two adjoining edges to fit—which is the case with the floating shelves shown below—I generally use a single panel of thin material as a template, scribing its edges individually.

For both strip and one-piece templates, you can use whatever thin sheet goods you have lying around—anything from 1/8-in. door skin to 1/4-in. MDF. There are packs of templating strips available for purchase, but I make mine from waste pieces of the same types of material, ripping 2-in.-wide strips that I bundle up for later use. For gluing, an inexpensive craft hot-glue gun will do the job, but I’ve recently started using a cordless construction-grade gun for convenience.

Strip templates for fitting three or more edges

This set of floating shelves needed to fit into a very irregular space where two cabinets meet a drywall corner and create four surfaces for fitting. This was a perfect situation for a strip template. Because these shelves were attached by screwing through the sides of the cabinet, rather than being placed on brackets, there was no built-in way to hold the template strips at the right level, so I attached temporary cleats to the cabinets to support the strips as I assembled the templates. I attached them from the back side of the cabinet sides, using the same screw holes I would later use to attach the shelves.

Templating includes scribing

To capture irregularities on the mating surface, you usually have to scribe the template stock so you can transfer the profile to the finished material later. I use a few different scribing tools, but my favorite is the Thingamejig from Specialty Tools. While other tools will work, the Thingamejig marks with a built-in knife, creating a more precise line.

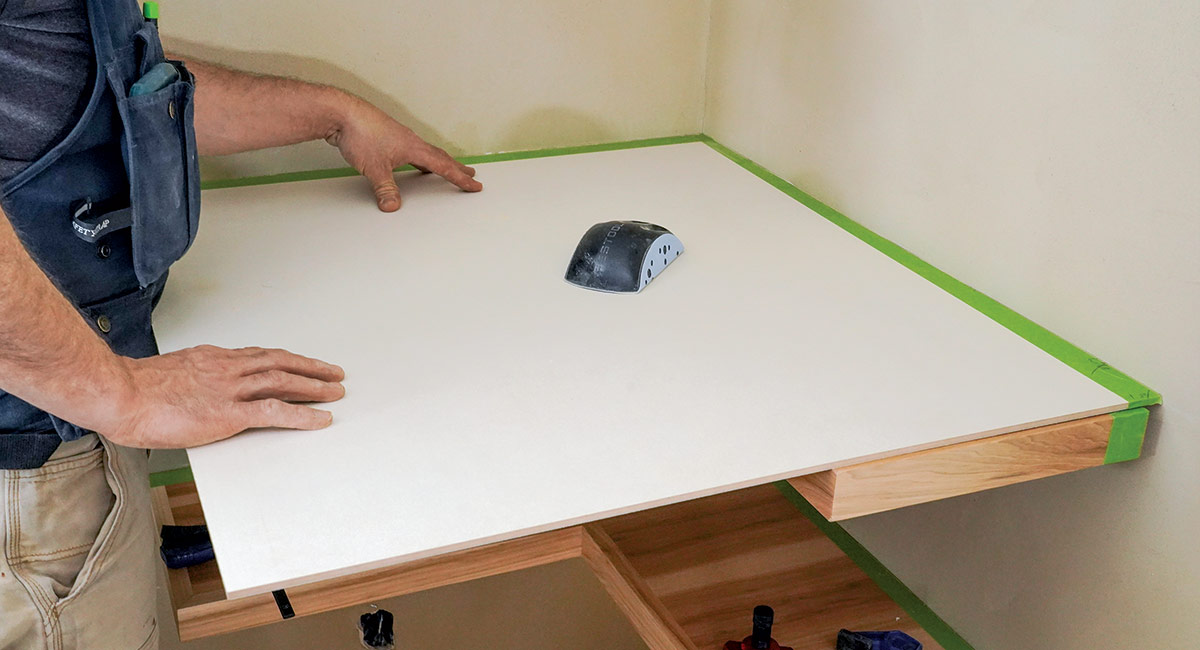

To make that knife line much more visible, I first apply brightly colored painter’s tape to the edge of the template (and the finished workpiece), then slice the tape with the Thingamejig and peel away the waste. Once the template is fit perfectly to the space, it’s easy to position it on the finished piece and transfer the shape for cutting. I often add notes or marks to the template to indicate things such as its proper location on the finished piece, the radius of a corner, or an area for back-beveling. To transfer the shape of the template to the workpiece, I also use bright-green painter’s tape and a sharp cutter. In this case, it’s a utility knife, run against the edge of the template. Apply just enough pressure to cut the tape. Pushing down too hard can cause it to follow the grain of the part below and pull away from the template.

To trim both the template and the finished part, I tend to use similar tools. I generally start with a track saw for the main cuts, as a belt sander tends to create too much dust, making it hard to see the line. On thick finished workpieces, I often follow with a power planer to get even closer to the line. After that I use a block plane or sanding block to adjust for fine irregularities. Once the final piece is shaped, I do a dry fit and occasionally remove a little more material. You can even re-scribe individual edges at this point. But be careful not to remove too much material here. Once your reference lines are gone, it’s easy to create compounding problems with the fit or to accidentally move the piece away from its desired position. Even at relatively straightforward junctions, I find myself templating rather than measuring. It’s almost always faster in the end, and I get peace of mind and perfect results.

Simple one-piece templates for fitting two edges

One common templating situation is when a countertop or shelf touches two walls. Between framing irregularities and drywall mud, such “square” corners are usually anything but. The floating corner shelves here needed to be fit to two walls, so I made a one-piece template out of a single panel of 1/4-in. MDF—the perfect material for templates. The first step is making the templates the same dimensions as the shelves.

With any templating job, you want to scribe or build the template as close as possible to the position of the finished piece to be sure you’re capturing the irregularities at that specific location. For countertops, this is straightforward: The template rests on the cabinets below. It was easy for these corner shelves, too; I just slid the shelves temporarily onto their brackets and clamped the template panels on top of them to scribe their back edges. The brackets, made from welded steel, are hidden behind the drywall (Floating Countertop Wall Bracket from IronSupports.com).

To create the slots hidden inside these thick shelves, I routed cavities in each of the plywood layers before gluing them together and edging them with solid wood. A similar technique was covered in Floating Shelves on Display (FHB #247).

Stefan Straka is a cabinetmaker and finish carpenter. Originally based in Bellingham, Wash., he recently emigrated with his family to Nelson, New Zealand.

Photos by Asa Christiana, except where noted.

From Fine Homebuilding #312

RELATED STORIES

View Comments

https://packstrack.com/