Podcast Episode 681: Rotting Trim, Concrete Roofs, and DIY Radiant Floor

Listeners write in about tools and California wildfires before asking questions about rotting exteriors, leaky garage roofs, and replacing concrete basement floors.

Welcome to the Fine Homebuilding podcast, our weekly discussion of building, remodeling, and design topics aimed at anybody who cares deeply about the craft and science of working on houses. This is senior editor Patrick McCombe. I’m joined by Fine Homebuilding editorial director Brian Pontolilo, associate editor Grant Baver, and producer Andres Samaniego. Please email us your questions to [email protected].

You can find previous podcasts and check out the show notes at finehomebuilding.com/podcast

|

Check in:

Brian: BS* + Beer course

Patrick: Upcoming BS* + Beer Symposiums

Listener Feedback 1:

Rob from New Jersey writes:

Hey Podcast Team,

Episode #675 about tools really got me thinking… As a DIY-er, and probably a pretty serious one at that, I’ve acquired my fair share of tools over the years with all the jobs I’ve done on my house. Many times its been easy to justify getting tools because either it was necessary to complete a specific job or I knew it would pay for itself many times over with the money I’ve saved through sweat equity.

However in recent years, I felt like I kept falling for the seemingly endless thinking traps that were produced by the emails/notifications from retailers I’ve purchased tools from, as well as emails from tool manufacturers I have registered tools with. I refer to them as thinking traps, because it took some time for me to realize that while I am their customer, in most cases I’m not their target audience…that is, I work on Wall St…not in the trades.

In other words, just like a professional musician can make a crappy instrument sound very good, if you’re good with your hands, chances are you can achieve very good results without breaking the bank on tools. For example, sticking with pneumatic nail guns vs. battery-powered nailers or maybe using a hand-me-down corded tool (with new blades/bits) vs. a new cordless one.

So, younger DIY listeners do yourself a favor—constrain those single-click tool purchases to the basics and a few “luxuries,” and focus your mental calories on making your workspace cleaner and more efficient, rather than pondering that new tool that’s only “a little pricey” but also only makes sense for a pro in the trades.

Thanks for listening. I’m looking forward to more “Show Us Your Shop” content, as I’m in need of ideas to make my tiny garage shop more efficient!

Rob

RELATED STORIES

Listener Feedback 2:

Charles writes:

Hey FHB team,

I love your podcast, your magazine, and the content.

I was just listening to episode #675 and your discussion on wildfire recovery in Los Angeles. We lost our home in the 2018 Camp Fire in Paradise, Calif. It destroyed 14,000 structures and almost all the housing in our town. We rebuilt our home and at the same time developed a disaster-recovery nonprofit to help with the rebuild process. I am in the trades doing commercial and residential repair work and am familiar with a lot of the nuances that our local jurisdictions modified to help in the recovery process. We developed programs such as grants programs to help individuals in the recovery process.

Also, to Mike and his friends with a young family who lost their home. Feel free to have them reach out to me at any time. When we went through our fire and lost our home, my boys were six and eight. The challenges are huge, but with enough perseverance, you can get through it. We changed schools and relocated to a different community until we got rebuilt. I’m happy to chat with them or just listen.

Anyway, I love what you guys do. If you want to spend more time on this topic, I would gladly offer up any resources and time to support the effort because it is a huge lift.

Keep up the great work!

Charles

RELATED STORIES

Question 1: I have a plan for fixing trim around a sliding glass door. Will it work?

Matt writes:

Hi podcast crew,

I work as a handyman and a client has asked me to do some repairs on rotting exterior trim on their house. The issue seems to go a little deeper than it first appeared, so I wanted to run it by you to get your thoughts.

Some background context on the house: It’s technically a renovated 1940s house, but with almost none of the original house left. The builder used a loophole to do a full teardown and rebuild that would otherwise not be allowed by zoning (by working on half the house at a time). There’s an 8-in. strip of original foundation in the basement that marks the boundary between the two stages. The house was completed in 2007, right when the housing market was collapsing, and you can see where they started cutting corners. For example, some of the side windows are trimmed in what looks like leftover metal flashing or gutter material. I assume because they were scrounging for scraps rather than ordering new material.

They have a double sliding glass door exiting to their deck on the rear of the house, with fixed glass panes on either side. The wooden trim on the bottom of these windows is rotting. I started digging out some of the rotten wood to see what was going on and quickly got to bare OSB sheathing that was also rotting. I can see what looks like Tyvek housewrap behind the sheathing, but nothing is on top of it. It also looks like almost all the windows have similar issues, but the owners are punting on that and focusing on this one section for now.

My plan is to pull away the trim and siding until I get to sheathing that isn’t rotten, then cut out the damaged part and patch in new sheathing. I’m going to pull up the deck board closest to the house to check the flashing on the ledger board, and fix that if necessary. I’m also going to suggest replacing the wooden trim with something synthetic and rot resistant like AZEK.

Here are some specific questions:

- What’s the deal with the housewrap being behind the sheathing? This is in the DC suburbs, climate zone 4.

- Can I use Zip sheathing to replace the rotten sections—to add some resiliency to the repair—or would that not work well with the housewrap being behind the sheathing?

- Is there anything else I should be doing to keep this problem from recurring beyond the plan I described above?

- Is this actually a much more significant problem and should I be referring them to a full-service contracting company instead?

Let me know what you think.

Thanks,

Matt

|

|

RELATED STORIES

- Repairing Exterior Trim

- Protect Board Ends to Prevent Rot

- Window Replacement With a Side of Rot Repair

Question 2: How do I waterproof a concrete dome?

Kurt writes:

Hi FHB crew!

I’m writing to you again from soggy Seattle. Thank you for all of the advice last year about the basement encapsulation for our 1906 house; in the end, since I have some shred of sanity, we ended up hiring a company to do both the seismic retrofit and basement encapsulation work. It was better than spending my entire summer doing it! Of course, I had to handhold them the entire way since their quality control was about zero. They didn’t follow the appropriate nailing schedule, improperly installed concrete anchors, had incomplete air-sealing details, and the list goes on and on. Not surprisingly, they didn’t take care of the rim joist very well (just crammed in fiberglass batts), so I’m buttoning that up this spring with some cut-and-cobble rigid foam.

Anyway, now it’s time to put some effort into our garage to increase its waterproofness. It’s a domed concrete one-car space that is partially inset into the slope. The roof has a few cracks (it’s also almost 120 years old), but it’s structurally sound. The plan is to repair the cracks before waterproofing. I don’t necessarily want to do EPDM or a membrane, so what are some other options that you’d recommend for this? I’m planning to use the space for storage and as an occasional workshop, so I have to solve the bulk-water problem!

What am I missing?

Thanks!

Kurt

Hey Kurt,

Concrete roofs can be tricky. It sounds like you might want to look into a fluid-applied roof coating/membrane to best suit the dome geometry. One option is a silicone or rubberized roof coating. The first that came to mind for me is from WR Meadows (Silicone Roof Coatings – Silicone Roofing System (Commercial) ). A bunch of other companies also make these, such as Henry Co., Grace, and Sika. I haven’t researched them enough to be able to say if one is better than the other, but hopefully that gives you a place to start your research!

Another option that comes to mind is called a cementitious slurry waterproofing, which is a specific product used to waterproof concrete. The major brand that comes to mind is Xypex.

I hope that helps at least give you a starting point for product research!

Thanks for listening!

GB

RELATED STORIES

Question 3: What’s the best plan for installing heated floors in a basement?

Scott writes:

Hi Fine Homebuilding podcast crew,

I’m looking for some feedback on a basement assembly I’m planning for my row home in Philadelphia.

I’m a licensed general contractor specializing in handyman services and small renovations. I’m finishing my basement and will soon have a concrete company pour a new slab with the standard 4 in. of gravel, a vapor barrier, and 4 in. of concrete. The concrete-to-joist height will land around 7 ft. 4 in. to 7 ft. 5in., so I have about 31/2 in. to work with for the floor and ceiling finishes to maintain 7 ft.

Because I installed heated floors upstairs, I have an open zone on my manifold for the basement. Initially I considered using foam panels with grooves for tubing, but the cost is substantial—around $5,000 for Uponor’s Xpress Trak for the foam alone. I recently saw someone create their own grooved panels using a router on XPS, which sparked an idea.

Here’s my proposed assembly, and I’m open to any criticism:

* 2-in. XPS insulation with manually routed 3/4-in. grooves

* Aluminum heat transfer plates pressed into the grooves

* Engineered hardwood laid directly over the XPS

I’ve read that engineered hardwood can be installed directly on XPS. This setup would cost approximately $900 for 490 sq. ft. of XPS and aluminum transfer plates, which is significantly less than the $5,000+ for prefabricated options like Uponor.

Being a row home, the neighboring basements buffer vapor drive from the fieldstone foundation walls, and with the new slab incorporating gravel and a 6mil poly vapor barrier underneath, do you foresee any issues with this assembly?

I’ve attached a screenshot for reference.

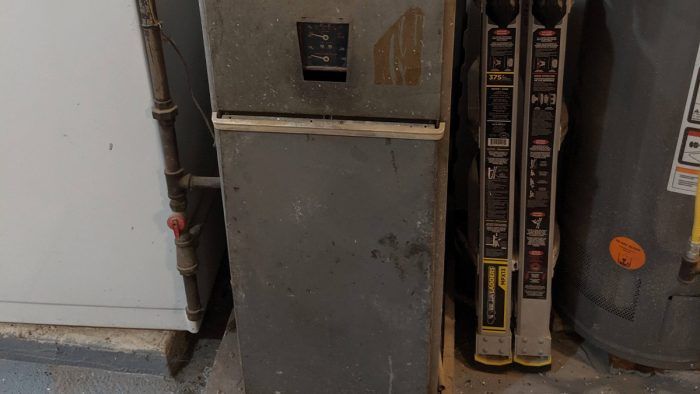

Also, I wanted to share a story of how this project became possible, which you might find amusing. A local HVAC company had a promotion seeking Philadelphia’s oldest (working) heater for a free replacement. I won with my fully functional boiler from 1951. I asked if I could pay the difference and install a high-efficiency Combi boiler, and they said yes. With a $3,000 gas company rebate for switching to high efficiency, the 199k BTU Combi boiler cost me only $1,500 out of pocket, fully installed. The variable-temperature system has made installing heated floors myself straightforward. Additionally, I’ve repurposed my now-defunct chimney into a laundry chute from my second-floor bedroom to the basement. I’ve attached a photo of the 70-year-old boiler. My only worry is the old boiler might have lasted longer than the new Combi boiler.

Thanks for your insights.

Best,

Scott Hicks

Fishtown Handyman

|

|

RELATED STORIES

- Dos and Don’ts for Electric In-Floor Heating

- Placing and Finishing a Heated Floor

- Planning and Prepping for a Basement Floor

Sign Up for an All-Access Membership

Unfortunately, that is all the time we have for today. Thanks to Grant, Brian, and Andres for joining me and thanks to all of you for listening. Remember to send us your questions and suggestions to [email protected] and please like, comment, or review us no matter how you’re listening–it helps other folks find our podcast.

Happy Building!

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Affordable IR Camera

Handy Heat Gun